Decades of Premier Packaging Solutions

Founded in 1954, EFP, LLC. is a leader in protective packaging, consumer packaging, cold chain solutions, and packaging supply chain services. Headquartered in Elkhart, Indiana, EFP has locations in Evansville, Indiana, La Vergne, Tennessee, Decatur, Alabama, and Reno, Nevada providing coverage to the west coast and mid-America from Canada to the Gulf of Mexico. EFP is owned by J.B. Poindexter & Co., a privately held, diversified manufacturing company with operating subsidiaries throughout North America. EFP is committed to innovating current products, creating sustainable solutions, and providing services that support our corporate purpose of Protecting What Matters.

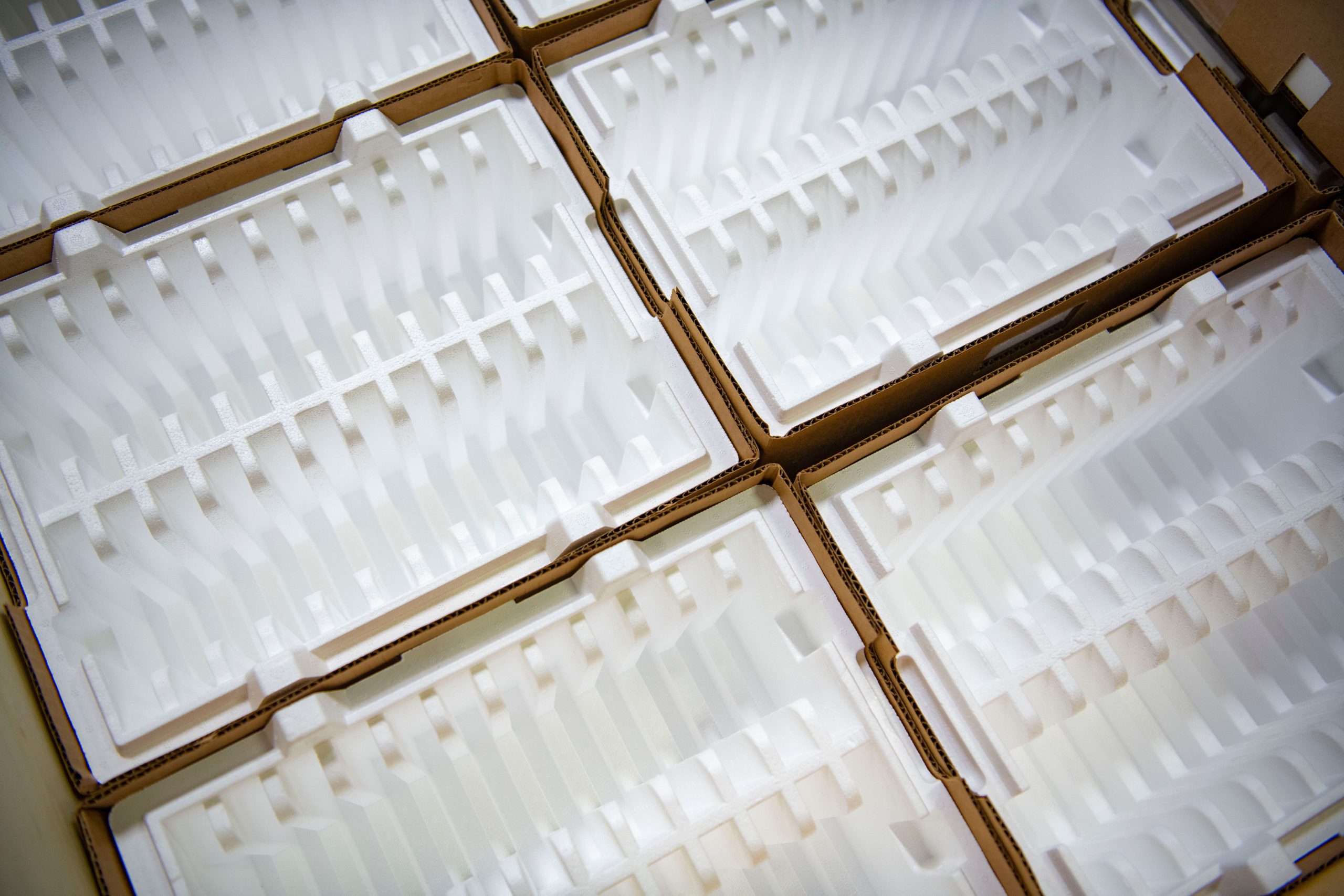

Protective Packaging

Protection and Distribution

Temperature Solutions

Ideation to Conception

Questions?

Call (574) 622-5768

Join Our Team

Our commitment to being a responsible, caring employer, and our focus on continual improvement has been key to our nearly 70 years of success.

Asembia’s AXS24 Summit

EFP exhibits at Asembia‘s AXS24 Summit in Las Vegas, Nevada from April 28th to May 2nd!

Cold Chain Stocking Program

We’re thrilled to announce the launch of EFP’s brand new cold chain Stocking Program.

ISTA Forum 2024

Dive deeper into the exciting world of packaging innovation with EFP at the ISTA International Safe Transit Association Forum this month!

Get In Touch

Whether you’d like to get to know more about EFP, learn more about our career opportunities or if you’d like to potentially do business, we’d love to talk with you.